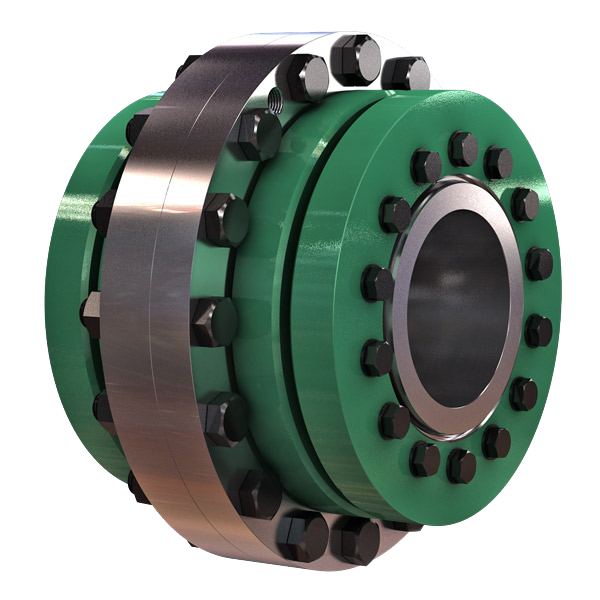

Product Description

Ductile Iron flange adapter with PN10/16 coupling for Ductile Iron Pipe fitting

The flange adapter transmits the pressure and thrust of the connected parts (blind plate force) and compensates the pipeline error, so as to reduce the damage of the axial thrust to the pipeline and pipeline equipment. It is mainly used for loose sleeve connection of pump, valve, pipeline and other accessories.

Specifications

Body: Ductile iron

Bolts: Galvanized steel / Stainless steel

Seal gasket: EPDM

Coating: CZPT Epoxy

Class: PN10/16, 125/150Lbs

Size:DN50-DN600

|

Size |

DN50-DN300 |

|

Standard |

ISO2531/EN545/EN598/AWWA |

|

Pressure |

PN10/PN16/PN25 |

|

Material |

Ductile Iron GGG50 material with FBE coated |

|

Coating |

Fusion bonded epoxy coating(250 micron) |

|

Color |

Blue FBE / Epoxy Coating |

|

Connection Type |

Flange Joint |

|

Gasket |

EPDM, SBR/NBR also available |

|

bolt nut |

Steel 8.8 zinced/Dacro |

Our Factory

HangZhou Fluido Import and Export Co.,Ltd. is a professional flange, pipe fittings,valves and ductile iron pipe fitting manufacturer and exporter for water treatment, construction, petrochemical and oilfield industry. We deliver exceptional value by providing customers with the most important elements : Premium Quality, Reasonable Price and Impeccable Services.

Our products adhere to GB, JIS, DIN, DIN, EN, API, ANSI/ASME specifications for material content, pressure ratings and quality assurance, ensuring that our customers receive consistent quality and reliability every time. Additionally, we are able to modify existing products or manufacture new designs to meet specific requirements.

We have been known as a company who always keeps our promise of quality products, reasonable pricing, and prompt delivery. By providing a broad range of high quality products at competitive prices, We see ourselves not just as a supplier for our clients, but as their partner in helping them achieved their own goals and objectives.

Package as customized

Certifications

Other Related Product

Our Services

1. Many years experience in manufacturing and exporting fittings

2. Experienced technical staff

3. Marking the customer’s brand on the product surface directly

4. All fittings are approved by CE and ISO

5. Supply OEM service

6. Small orders accepted

7. Competitive prices, top quality, professional service and prompt delivery

8. Quality checking and controlling strictly

FAQ

Q:When can I get the quotation?

A:We usually quote within 12 hours after we get your inquiry.If you are very urgent to get the price,pls call us or tell us in your email so that we will regard your inquiry priority.

Q: Could I get samples?

A: Yes,we have materials in stock to help you to get the samples as soon as we can.

Q:Can you do the design for us?

A:We have a professional team having rich experience in manufacturing.We could supply customized size,grade of material,and the coating.We also could supply the package according to your request.

Q.How are orders packed and shipped ?

A: For custom order, we can design full-color custom packaging to match your brand, if requires. Most shipments include boxes packed inside an outer carton and placed on a wooden pallet.

Q:What abount the lead time for mass production?

A:Honestly,it depends on the order quantity and your specific requirements of products.

Q.What are your quality control procedures?

A: We adhere to strict quality control procedures that begin with product design and carry through to the end of the production process using state-of -the-art quality control equipment.

Factors to Consider When Choosing a Flange Coupling for a Specific System

When selecting a flange coupling for a specific system, several factors need to be taken into consideration to ensure optimal performance and reliability. Here are the key factors to consider:

- 1. Load and Torque Requirements: Determine the maximum load and torque that the flange coupling will experience in the application. This includes both static and dynamic loads. Select a flange coupling that can handle these loads without exceeding its rated capacity.

- 2. Shaft Diameter: Measure the diameter of the shafts that will be connected by the flange coupling. Ensure that the coupling’s bore size matches the shaft diameter to provide a proper fit and secure connection.

- 3. Misalignment Tolerance: Consider the amount of misalignment that the system may experience during operation. Flange couplings are available in different designs, and some can accommodate higher levels of misalignment than others. Choose a coupling that can handle the expected misalignment to prevent premature wear and stress on the system.

- 4. Operating Speed: Determine the rotational speed of the connected equipment. High-speed applications may require precision balancing and careful selection of materials to prevent issues like resonance and excessive vibration.

- 5. Environmental Conditions: Consider the environmental factors the flange coupling will be exposed to, such as temperature, humidity, dust, and chemicals. Choose a material and coating that can withstand the specific environmental conditions to prevent corrosion and degradation.

- 6. Space Limitations: Evaluate the available space for installing the flange coupling. Some applications may have limited space for coupling installation, requiring compact designs or custom solutions.

- 7. Serviceability: Assess the ease of installation and maintenance of the flange coupling. A coupling that is easy to install and service can reduce downtime and maintenance costs.

- 8. Compatibility: Ensure that the flange coupling is compatible with the equipment and shafts in the system. Consider factors such as keyways, set screws, and other connection methods.

- 9. Material Selection: Choose the appropriate material for the flange coupling based on factors like load, temperature, and corrosion resistance. Common materials include steel, stainless steel, aluminum, and various alloys.

- 10. Cost: Compare the cost of different flange coupling options, considering both the initial investment and long-term maintenance expenses. Balance the cost with the desired performance and reliability.

It is essential to consult with coupling manufacturers or industry experts to ensure the flange coupling’s suitability for the specific application. Properly selecting and installing the right flange coupling can contribute to the efficiency, reliability, and longevity of the connected machinery and system.

Common Installation Mistakes to Avoid When Using Flange Couplings

Proper installation is crucial for the efficient and reliable operation of flange couplings. Avoiding common installation mistakes can help ensure the longevity and optimal performance of the coupling. Here are some common installation mistakes to avoid:

1. Improper Alignment: One of the most critical aspects of flange coupling installation is ensuring proper shaft alignment. Misalignment can lead to increased wear, vibrations, and decreased power transmission efficiency. Always use precision alignment tools and techniques to achieve accurate alignment.

2. Over-Tightening: Over-tightening the coupling’s bolts can cause excessive stresses on the coupling and connected equipment. It may lead to premature failure or deformation of the coupling. Follow the manufacturer’s recommended torque values for tightening the bolts.

3. Under-Tightening: On the other hand, under-tightening the bolts may result in a loose connection, leading to misalignment and potential damage to the coupling during operation. Make sure to achieve the proper torque during installation.

4. Lack of Lubrication: Insufficient or improper lubrication of the coupling’s components can result in increased friction and wear. Follow the manufacturer’s guidelines for lubrication, and use the recommended lubricant to ensure smooth operation.

5. Contamination: Avoid introducing dirt, debris, or foreign particles into the coupling during installation. Contaminants can lead to wear and damage over time, reducing the coupling’s performance.

6. Incorrect Coupling Selection: Choosing the wrong type or size of flange coupling for the application can lead to performance issues. Consider factors like torque, speed, load, and operating environment when selecting the coupling.

7. Lack of Inspection: After installation, regularly inspect the flange coupling and its components for signs of wear, damage, or misalignment. Early detection of issues allows for timely maintenance and prevents potential system failures.

8. Ignoring Manufacturer Guidelines: Always follow the manufacturer’s installation instructions and guidelines. Each flange coupling may have specific requirements and recommendations that must be adhered to for proper functioning.

9. Incorrect Shaft Fit: Ensure that the coupling properly fits the shafts’ dimensions. A loose fit can cause slippage, while a tight fit can lead to stress concentration and premature failure.

10. Inadequate Inspection of Components: Before installation, inspect all coupling components, including flanges, bolts, and keyways, for any defects or damage. Replace any damaged parts before installation.

By avoiding these common installation mistakes, you can maximize the performance and lifespan of flange couplings in your mechanical systems.

What is a flange coupling and how does it work?

A flange coupling is a type of rigid coupling used to connect two shafts together in a mechanical system. It consists of two flanges, one on each shaft, which are bolted together to form a solid and robust connection. Flange couplings are widely used in applications where precise alignment, high torque transmission, and zero backlash are critical.

The key components of a flange coupling include:

- Flanges: The flanges are circular discs with holes around the perimeter for bolting them to the respective shaft ends. The flanges are made from materials such as steel, cast iron, or aluminum, depending on the application requirements.

- Fasteners: High-strength bolts or studs with nuts are used to fasten the flanges together securely. The number and size of the bolts depend on the size and torque capacity of the coupling.

- Gaskets: In some cases, gaskets or spacers are used between the flanges to provide insulation, prevent corrosion, or compensate for any slight misalignments between the shafts.

How a flange coupling works:

- The two shafts that need to be connected are brought together with their respective flanges facing each other.

- The flanges are aligned precisely to ensure that both shafts are in perfect axial alignment. Proper alignment is essential to prevent excessive loads on the bearings and to ensure efficient torque transmission.

- Once the flanges are aligned, high-strength bolts or studs are inserted through the holes in the flanges, and nuts are fastened tightly to hold the flanges together securely.

- The tight connection between the flanges creates a rigid joint between the shafts, allowing torque to be transmitted from one shaft to the other with minimal losses.

- Flange couplings are designed to have zero backlash, meaning there is no play or free movement between the shafts when the direction of rotation changes. This feature ensures precise and immediate power transmission between the connected shafts.

Flange couplings are commonly used in various industrial applications, including heavy machinery, pumps, compressors, and marine propulsion systems. They are preferred when a reliable, high-torque transmission with precise alignment is required. However, they do not offer flexibility to accommodate misalignment, which is a limitation compared to flexible couplings. Therefore, proper alignment during installation is critical to avoid premature wear and failure of the coupling and connected equipment.

editor by CX 2023-08-14