Product Description

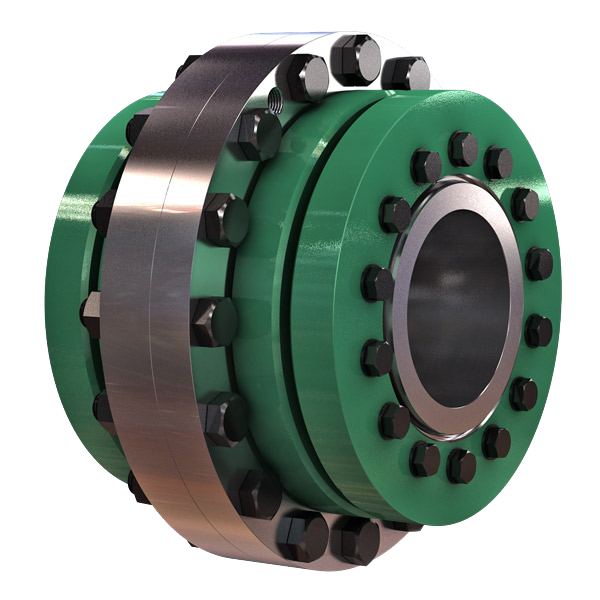

Cast Iron Steel Normex Flange Shaft Flexible Nm Coupling With Rubber

Product Description

1. Applies to flexibly drive shaft, allowing a more significant axial radial displacement and displacement.

2. It Has a simple structure and easy maintenance.

3. Disassembly is easy.

4. low noise.

5. Transmission efficiency loss, long useful working life.

Product Parameters

| SIZE | TORQUE | MAX SPEED rpm. |

BORE | BOSS DIA D |

OUTSIDE DIA OD |

LENGTH L |

TOLERANCE | POWER | SHAFT | WEIGHT kg |

||

| STHangZhouRD kg/m |

MAX kg/m |

MIN | MAX | |||||||||

| NM-50 | 1.3 | 2.3 | 13500 | 1 | 19 | 33 | 50 | 25 | 2.0±0.5 | – | – | 0.48 |

| NM-67 | 2.2 | 4 | 10000 | g | 28 | 46 | 67 | 30 | 2.5±0.5 | 1HP | 8-28 | 1.02 |

| NM-82 | 5 | g | 8000 | 10 | 32 | 53 | 82 | 40 | 3.0±1.0 | 2-3HP | 10-32 | 1.88 |

| NM- 97 | 10.5 | 19 | 7000 | 12 | 42 | 69 | 97 | 50 | 3.0±1.0 | 5-7.5HP | 12-42 | 3.54 |

| NM-112 | 16.7 | 30 | 6000 | 14 | 48 | 79 | 112 | 60 | 3.5±1.0 | 10-20HP | 14-48 | 5.4 |

| NM-128 | 26.7 | 48 | 5000 | 1B | 5 | go | 128 | 70 | 3.5±1.0 | 30HP | 18-55 | 8.1 |

| NM-148 | 41.7 | 75 | 4500 | 22 | 65 | 107 | 148 | 8o | 3.5±1.0 | 40HP | 22-65 | 13.5 |

| NM-168 | 69.5 | 125 | 4000 | 28 | 75 | 126 | 168 | 9o | 3.5±1.5 | 60HP | 28-75 | 19.3 |

Related Products

Company Profile

FAQ

Q: Can you make the coupling with customization?

A: Yes, we can customize per your request.

Q: Do you provide samples?

A: Yes. The sample is available for testing.

Q: What is your MOQ?

A: It is 10pcs for the beginning of our business.

Q: What’s your lead time?

A: Standard products need 5-30days, a bit longer for customized products.

Q: Do you provide technical support?

A: Yes. Our company has a design and development team, and we can provide technical support if you

need.

Q: How to ship to us?

A: It is available by air, sea, or by train.

Q: How to pay the money?

A: T/T and L/C are preferred, with different currencies, including USD, EUR, RMB, etc.

Q: How can I know if the product is suitable for me?

A: >1ST confirm drawing and specification >2nd test sample >3rd start mass production.

Q: Can I come to your company to visit?

A: Yes, you are welcome to visit us at any time.

Q: How shall we contact you?

A: You can send an inquiry directly, and we will respond within 24 hours /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

What Role Does a Flange Coupling Play in Reducing Downtime and Maintenance Costs?

A flange coupling plays a crucial role in reducing downtime and maintenance costs in mechanical systems. Here are the key ways it contributes to these benefits:

- Misalignment Compensation: Flange couplings can accommodate a certain degree of misalignment between the shafts, both angular and parallel. By allowing for misalignment, the coupling reduces the chances of mechanical failures caused by rigid connections. This flexibility minimizes stress and wear on the connected equipment and helps prevent unexpected downtime due to alignment issues.

- Vibration Damping: Flange couplings with flexible elements, such as elastomeric inserts, help dampen vibrations in the system. By absorbing and dissipating vibration forces, the coupling protects the equipment from excessive vibrations that could lead to component failure and unplanned downtime.

- Shock Load Absorption: In some applications, sudden shock loads or torque spikes can occur. Flange couplings with flexible elements have a certain shock-absorbing capacity, which prevents damage to the machinery and reduces the likelihood of unplanned downtime caused by sudden impact loads.

- Easy Maintenance and Inspection: Flange couplings are designed for easy installation, maintenance, and inspection. They usually consist of fewer parts and are accessible for visual inspections and lubrication. This ease of maintenance allows for quick identification of any wear or misalignment issues, enabling timely corrective actions to avoid costly breakdowns.

- Long Service Life: Flange couplings are typically constructed from durable materials that can withstand demanding operating conditions. When properly selected and maintained, they offer a long service life with minimal wear and replacement requirements. This longevity contributes to reduced maintenance costs and fewer replacement expenses over the equipment’s lifetime.

- Cost-Effective Design: Flange couplings are available in a variety of materials and configurations, offering cost-effective solutions for power transmission needs. Their relatively simple design and easy installation further contribute to cost savings during the initial setup and routine maintenance.

Overall, a well-chosen and properly maintained flange coupling enhances the reliability and efficiency of mechanical systems, reducing downtime, and lowering maintenance costs in industrial applications.

Can Flange Couplings Be Used in Food Processing and Pharmaceutical Industries?

Yes, flange couplings can be used in food processing and pharmaceutical industries, provided they meet certain requirements and standards to ensure hygiene and product safety. These industries have stringent regulations and guidelines to prevent contamination and maintain the quality and purity of their products. When selecting flange couplings for such applications, several considerations must be taken into account:

- Material Selection: The flange coupling material must be food-grade or pharmaceutical-grade and comply with industry-specific regulations. Stainless steel, particularly austenitic grades like 316L, is commonly used due to its excellent corrosion resistance and ease of cleaning.

- Hygienic Design: Flange couplings for these industries should have a hygienic design that minimizes crevices, dead spaces, and surface roughness where bacteria or contaminants could accumulate. Smooth surfaces and seamless construction help facilitate thorough cleaning and sterilization.

- Sealing and Lubrication: Proper sealing is essential to prevent any potential leaks or ingress of contaminants. Food-grade or pharmaceutical-grade lubricants should be used to ensure that there is no risk of contamination from the coupling’s lubrication.

- Certifications and Compliance: Flange couplings intended for use in food processing and pharmaceutical industries should have relevant certifications, such as FDA (U.S. Food and Drug Administration) approval, EU regulations (e.g., EC No. 1935/2004), and compliance with industry standards like 3-A Sanitary Standards.

- Cleanability: Flange couplings should be designed for easy disassembly and cleaning to maintain the required hygiene standards. This may involve quick-release or tool-less designs that allow for frequent inspection and cleaning without impeding production processes.

- Resistant to Corrosive Cleaning Agents: In food processing and pharmaceutical industries, aggressive cleaning agents may be used. The flange coupling material should be resistant to these substances to avoid degradation and maintain the coupling’s integrity over time.

By meeting these criteria, flange couplings can be safely used in food processing and pharmaceutical applications without compromising product quality or safety. It is crucial to work with reputable manufacturers or suppliers who understand the specific requirements of these industries and can provide couplings that adhere to the necessary standards.

Limitations and Disadvantages of Flange Couplings

While flange couplings offer several advantages, they also have some limitations and disadvantages that should be considered when selecting them for a specific application:

- 1. Size and Weight: Flange couplings tend to be larger and heavier compared to some other coupling types. This can be a limitation in applications where space and weight are critical factors.

- 2. Higher Cost: Flange couplings can be more expensive to manufacture and install compared to simpler coupling designs like sleeve couplings or clamp couplings.

- 3. Complex Installation: Installing flange couplings may require more time and expertise due to their intricate design and multiple components, including bolts and gaskets.

- 4. Rigidity: Flange couplings are relatively rigid, which means they may not accommodate as much misalignment as flexible couplings. Excessive misalignment can lead to increased stress on the equipment and coupling, potentially resulting in premature failure.

- 5. Bolt Stress: Proper tightening of the bolts is crucial for the effective functioning of flange couplings. Over-tightening or under-tightening the bolts can lead to bolt fatigue or coupling slippage.

- 6. Noise and Vibration Transmission: Flange couplings, especially rigid designs, can transmit more noise and vibration compared to flexible couplings, potentially affecting the performance and longevity of connected equipment.

- 7. Maintenance: Flange couplings may require more frequent maintenance due to the presence of multiple components and the need to periodically check bolt tightness and gasket conditions.

- 8. Corrosion: Depending on the material used, flange couplings may be susceptible to corrosion in certain environments. Corrosion can compromise the integrity of the coupling and reduce its service life.

Despite these limitations, flange couplings are still widely used in various industrial applications due to their robustness, high torque capacity, and ability to handle heavy loads. Proper application, installation, and maintenance can help mitigate some of these disadvantages and ensure the reliable performance of flange couplings in a wide range of systems.

editor by CX 2024-05-07